Project Update – July 27, 2020

For up-to-date information on traffic detours and speed reductions, please visit 511 Alberta.

We appreciate your patience during construction.

Bow River Bridge Time Lapse Photos

The time lapse video shows construction on the bridge piers on the north side of the river from September 2019 until mid-July 2020.

Dust and Mud On Valley Ridge Boulevard N.W.

We understand construction can be difficult for people living and working near the project and have set guidelines for the contractor to minimize public impacts. One of the concerns we’ve heard about lately is mud on Valley Ridge Boulevard NW.

The contractor is required to implement dust management plans which include watering the site. Unfortunately, mud is sometimes a side effect of keeping the dust controlled. To manage the mud on the road, the contractor has been having sweepers and scrapers clear the area frequently.

Bridge Pier Construction

Bridge pier construction on the north and south side continues. On the south side, pictured below, a third tower crane is up, work on the cofferdam continues and piling for the bridge pier closest to Valley Ridge is ongoing.

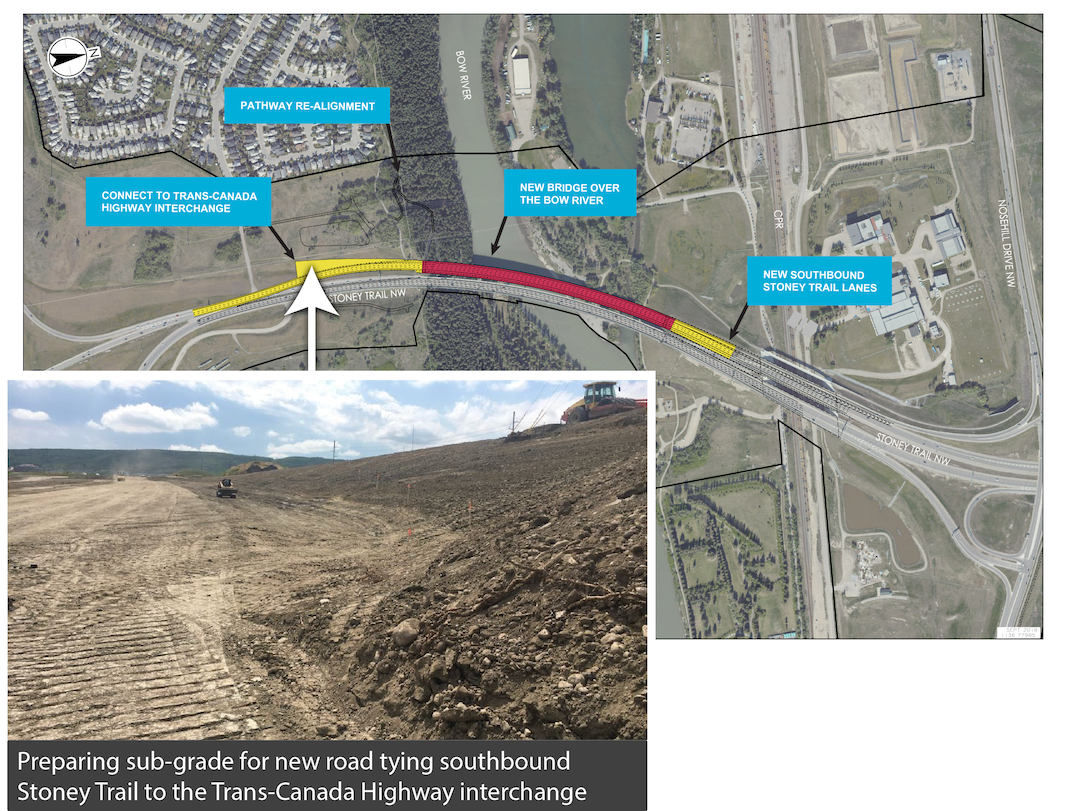

Southbound Stoney Trail Roadworks

Roadwork continues on the missing link that will connect the new bridge with the Trans-Canada Highway interchange.

Snapshot of Work Completed in June

June was another challenging month for weather. With a hailstorm estimated to have caused $1.2 billion in damage (Canada’s 4th costliest natural disaster ), thunderstorms and more rain than the monthly average, there was a lot of mud and water pumping happening on site. Still, EllisDon and its subcontractors worked 67,157 work hours in June with social distancing and other COVID protocols remaining in place. That’s nearly 20,000 more hours than in May and the equivalent of 90 hours worked every hour of every day for the entire month!

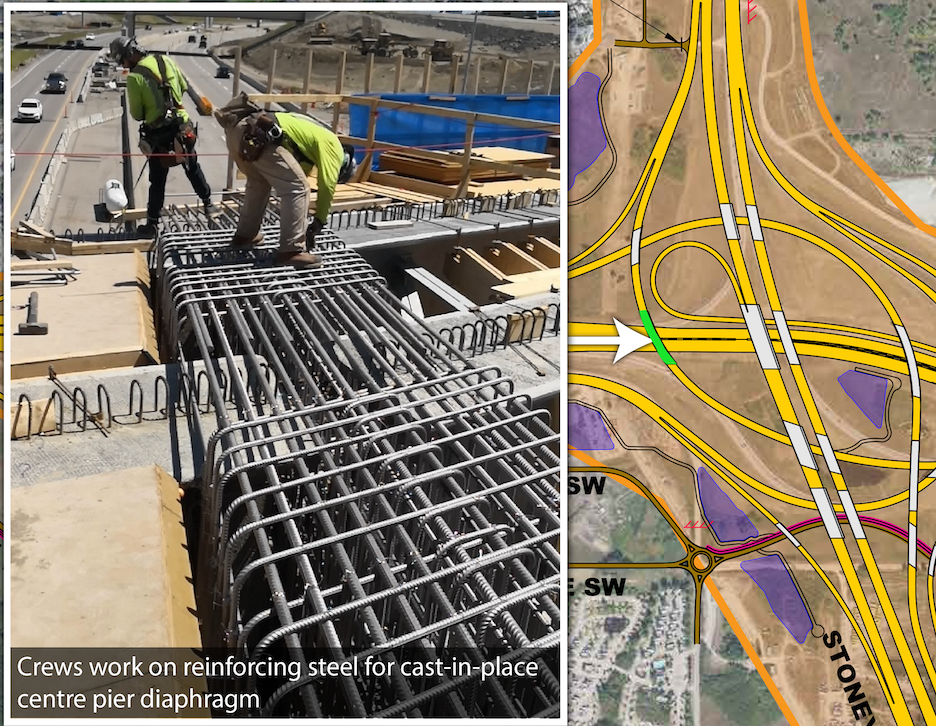

Trans-Canada Highway/Stoney Trail Interchange

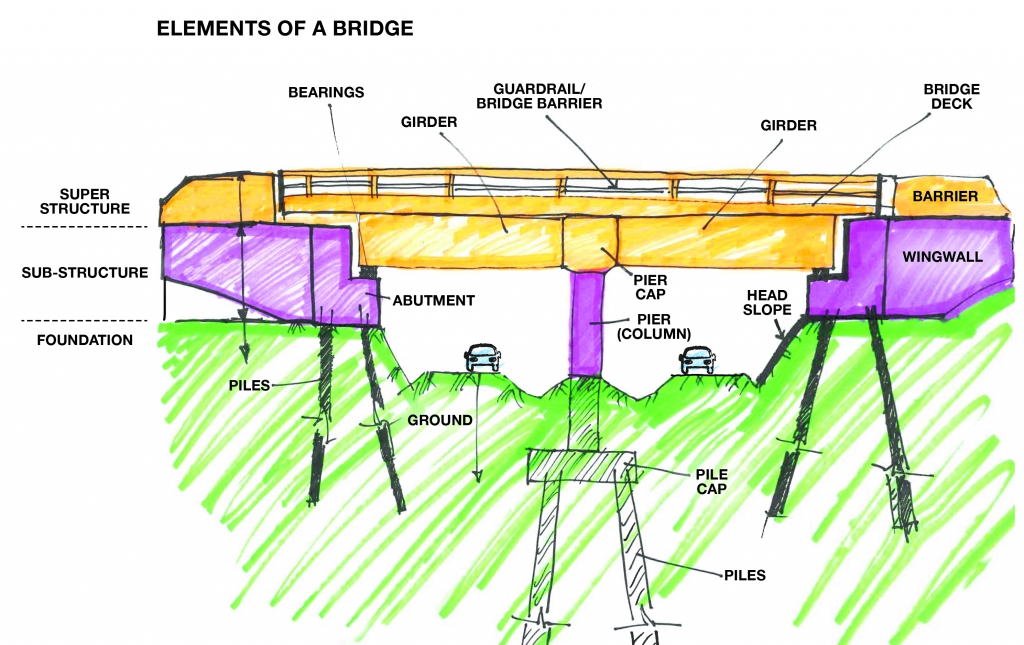

Cast-in-place concrete diaphragms (or cross-frames) form the permanent connection between the bridges’ sub-structure and super structure.

The concrete diaphragms are placed between girder ends at the centre pier, and behind girder ends at the abutments.

Trans-Canada Highway/Valley Ridge Boulevard N.W. Interchange

Another day, another deck pour! With 20 bridges on the project, lately it seems like we’re lifting girders and pouring bridge decks every other day. Tonight, if the weather allows, crews will pour the bridge deck for one of three bridges required for the Valley Ridge Boulevard N.W. interchange.

Foundation for the mechanically stabilized earth (MSE) wall is ‘proof rolled’ to ensure the soil is compacted to the required standard

With the foundation inspected and approved, crews install the concrete footings, or leveling pad, for the MSE panels

With the footings in place, the first of the MSE panels are installed with filter fabric at the joints to prevent erosion but allow drainage

Backfill is placed behind the retaining wall to the west of the MSE wall

Same wall a month ago today – progress!

Stormwater Management

There is a total of ten Stormwater Management Facilities (SWMFs) within the North Project: eight wet ponds and two constructed wetlands.

Also known as granular B gravel, pit run is a blend of sand and stone. The sand is separated out during the screening process, and the remaining screened rocks are excellent for drainage and providing a stable base for landscaping, roadways, etc.

Utility Work on Old Banff Coach Road S.W.

The City of Calgary continues work on relocating the watermain to make way for the new interchange at Old Banff Coach Road S.W. This work will be ongoing until the fall. Please anticipate delays and plan accordingly.

Stable sidewalls are a requirement for all trench construction. Geotextiles, or filter fabrics, can reduce the trench width in areas where the native soil is very soft and/or migrates easily. They may also be placed on the trench bottom and sides to separate native soils from backfill material.

Steel “H” piles are structural beams driven in the ground for deep foundations. It is critical that the proper horizontal and vertical alignment of the piles be maintained during installation. This is achieved by using steel templates.

Typically, each pile is guided in with driving guides or templates, driving caps running on fixed leads, or a combination of the two.